We developed a new enzymatic transesterification process (ET Process®, patented) to address prevailing challenges in biodiesel production.

The ET Process® simultaneously converts both oil and free fatty acid into biodiesel using an immobilized lipase in an inert solvent environment. The ET Process® utilizes flexible feedstocks. Therefore, it can fit all kinds of vegetable oil or animal fat, crude or refined, fresh or used. Feedstocks like crude oil usually only need a degumming step as pretreatment for ET Process®.

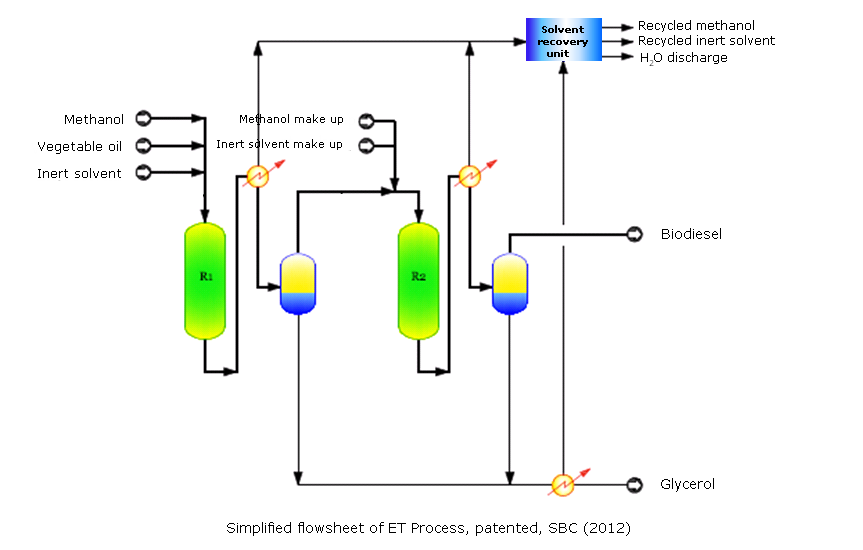

The ET Process® comprises of two reactors: a primary reactor and secondary reactor. The reactor can have a packed bed or CSTR design. The main products are pure biodiesel and pure glycerol which can be enhanced to pharma-grade.

The reaction typically falls within a 10-60 minute range and can be carried out close to room temperature (25-45°C). There is no chemical waste since ET Process® can fully recycle and reuse the alcohol reactant and inert solvent.

Find more: Advantages of ET Process®